If you need an 8-inch subwoofer that can create outstanding bass in extremely small enclosures, the 8W3v3 will do the job and surprise you with its power and accuracy. It employs the same technologies as its larger diameter brethren to deliver a whopping 0.375 in. (10 mm) of controlled, one-way, linear excursion. The 8W3v3-4 is best used with amplifier power in the 75W - 250W range and is optimized to operate in a tiny 0.30 cu. ft. (8.5 l) sealed enclosure, or a 0.35 cu. ft. (9.9 l) ported enclosure. Detailed enclosure recommendations can be found in the "Specifications" tab.

JL Audio's proprietary Dynamic Motor Analysis system is a powerful suite of FEA-based modeling systems, first developed by JL Audio in 1997 and refined over the years to scientifically address the issue of speaker motor linearity. This leads to vastly reduced distortion and faithfully reproduced transients... or put simply: tight, clean, articulate bass. DMA is able to analyze the real effects of fluctuating power and excursion upon the magnetic circuit of the motor, specifically the dynamic variations of the "fixed" magnetic field. This delivers intensely valuable information compared to traditional modeling, which assumes that the "fixed" field produced in the air gap by the magnet and the motor plates is unchanging. DMA not only shows that this "fixed" field changes in reaction to the magnetic field created by current flowing through the voice coil, but it helps our engineers arrive at motor solutions that minimize this instability.

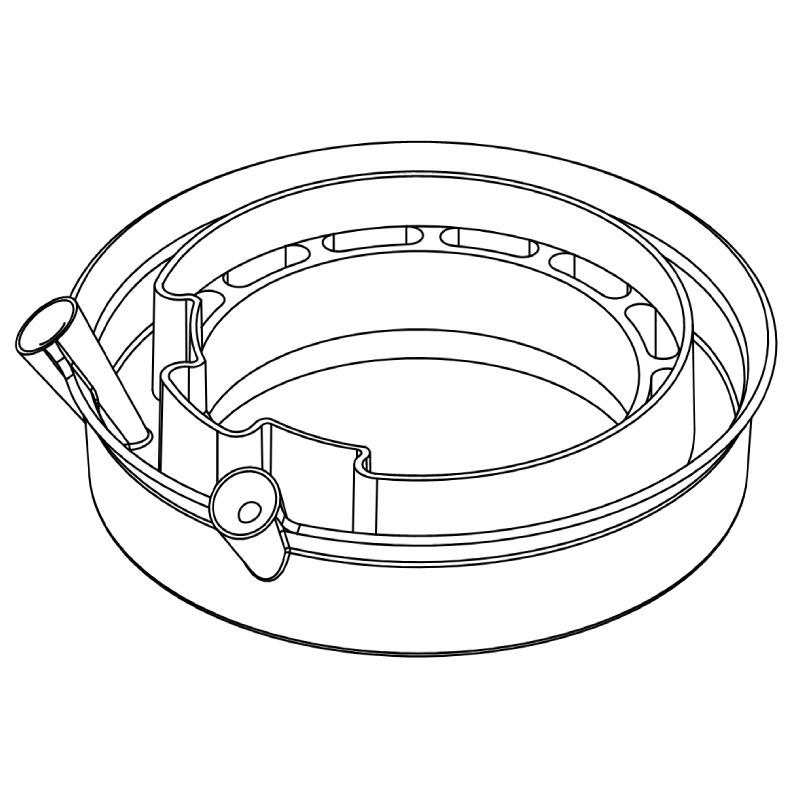

JL Audio's patented Elevated Frame Cooling design delivers cool air through slots directly above the top-plate to the voice coil of the speaker. This not only enhances power handling, but also sound quality by minimizing dynamic parameter shifts and power compression. Many speakers employ venting techniques to enhance voice coil cooling. This is typically accomplished by having big holes in the sides of the frame just below the spider attachment shelf. While it provides a modest cooling benefit, this low-velocity air-flow does not blow directly or strongly on the voice coil.

This assembly technique, conceived by JL Audio, ensures proper surround geometry in the assembled speaker for better excursion control and dynamic voice coil alignment. JL Audio's patented FCAM™ technology is an innovative method of bonding the surround/cone assembly to the voice coil former/spider assembly. This feature helps ensure concentricity of the surround, spider and voice coil without torquing the suspension to achieve it. This allows for the inevitable, slight variations in production part dimensions without having them negatively impact the integrity of the suspension and coil-centering at high excursions.

JL Audio's Vented Reinforcement Collar (VRC®) improves the rigidity and stability of the cone/spider/voice coil junction and directs airflow over the voice coil windings for improved thermal performance. The Vented Reinforcement Collar (VRC®) is a composite structure that addresses two issues related to reliability. By reinforcing the critical junction between the cone, voice coil and spider, the VRC greatly reduces failures due to glue breakdown or material weakness. It does this by greatly increasing adhesive contact area and providing stress relief to the spider material at excursion extremes.